Wooden Toy Car Plans

Part of a collection of wooden toy car plans. Based on the rumble seat roadster cars built in the 1930's, this single seat sports car features a dicky seat for an extra passenger. Sometimes called a mother-in-law seat.

This sporty little wooden toy car measures about 315mm (12.4 in) long, 160mm (6.3 in) wide and 115mm (4.5 in) high.

How to Make Toy Cars

The project is simple enough for beginners, yet interesting enough for toy makers with a little more experience. The challenge is in the method of construction.

Making toy cars is a lot of fun, they can be very simple profiles cut out with a band saw with a set of wheels attached.

This file contains the full size templates for the body parts, chassis and mudguards. Step by step instructions with photos are also included.

Simply print out each template page on your home printer, making sure the scale is set 1:1 or full size.

Materials

Most of the toys I have made using wood from the scrap bin or any timber I can find. These wooden toy car plans have been designed to use project timber available from your local hardware or timber supplier. Also known as one inch wood, or white wood it is ready to use for a project such as this.

Tools

This is a list of the tools I to nake this wooden toy car. Most woodworkers and home handyman already have most of these tools.

- Power drill.

- Scroll saw.

- Router mounted in a router table.

- Hand saw.

- Combination square

- Woodworking clamps.

- Hacksaw to cut the dowel axles to length.

- Sanding block with 120 and 80 grit sandpaper.

- A selection of drill bits.

Optional tools:

Some would say most of the pleasure of making toys is having the right tools to use. Everybody is different, some people would be happy to use the most basic of hand tools.

A router mounted in a router table is nice to have, but not essential to the completion of this project.

Likewise, I find a 12 inch disc sander very useful.

A drill press is also beneficial for making wooden toys, for drilling holes accurately for wheels and other moving parts.

I made my own wooden toy wheels using a circle cutter.

Step by Step Building Instructions

This is a preview of the building instructions which is part of the download package.

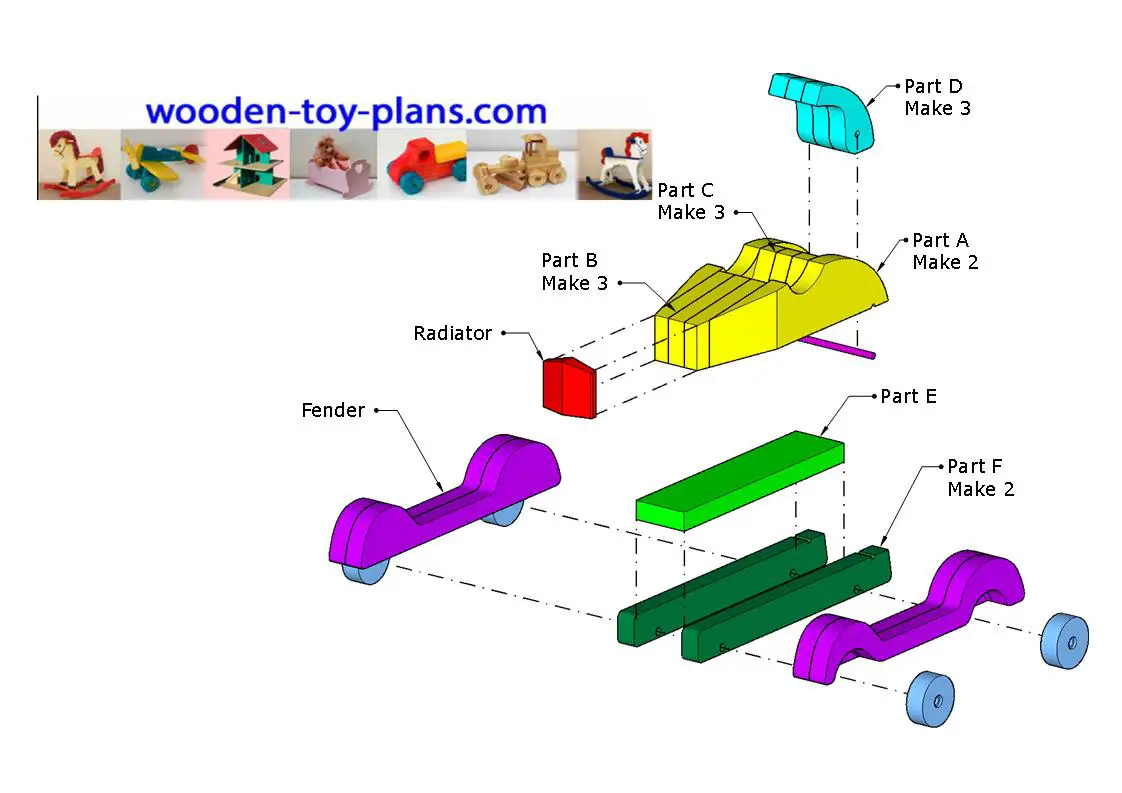

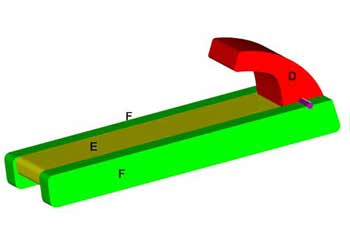

Exploded view showing how the parts fit together, colour coded for easier identification.

Step 1

Step 1

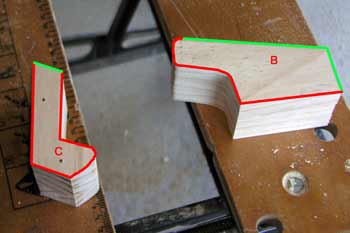

Step 1The photo shows the parts A to D cut oversize, ready for gluing.

Parts B, C and D are laminated to make a thickness of 1 1/2 inches or 57mm.

They way I work, I prefer to cut the parts oversize before gluing them together because I find that the pieces tend to creep under clamping pressure.

That was before I discovered a type of wood glue that does not require clamping.

In the photo I have drawn red lines to show that these are the areas to clean up for step 2.

Step 2

Step 2

Step 2In this photo I have cleaned up B and C.

The green lines indicate the areas to be left rough at this stage.

These areas are cleaned up in the next step.

Step 3

Step 3

Step 3Showing the two sides fixed in place.

The bonnet is cleaned up, but the green area is left rough.

Step 4

Step 4

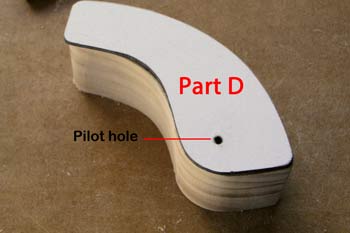

Step 4Here I have cleaned up part D.

Using the template to locate the pilot hole for the dowel pin.

This is where a drill press would come in handy. I don't actually have one, so I used a drill guide instead.

Step 5

Step 5

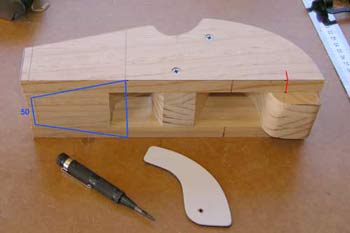

Step 5Position part D in the body sub-assembly, and mark the position of the pilot hole as shown by the red line.

We will use this mark to drill the hole for the hinge pin when the chassis is fixed in place.

The blue line indicates the shape of the bonnet to be cut out in the next step.

Step 6

Step 6

Step 6Cutting the bonnet with a band saw. You could use a hand saw instead.

Sand everything smooth and round over the top edges ready for assembly.

Step 7

Step 7

Step 7The chassis sub assembly in glorious technicolor. Note that the overall width should match the bodywork.

Part D, shown red, is in position with the hinge pin in a complementary shade of purple. This is purely for illustration purposes, the hole for the pin will be drilled at a later stage.

Be sure to leave a small gap between part E (yellow) and part D (red) to allow it to rotate freely.

Step 8

Step 8

Step 8Fix the chassis to the bodywork. I used four wood screws as shown by the blue dots.

The red dot on the side indicates the hole for the hinge pin, as located in step 5. Drill the hole and fit the rumbler seat.

No doubt it will be a bit tight, so we need to shave a bit off. Check for movement and adjust accordingly.

Step 9

Step 9

Step 9With the rumble seat in place, the area shaded red is sanded smooth, and the seat is rounded over.

Step 10

Step 10

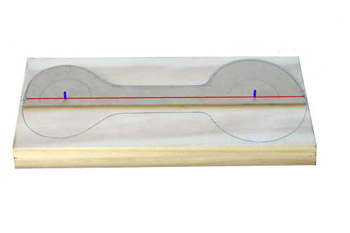

Step 10Now make the mudguards using a template. The red line indicates the centerline and the two blue lines are a pair of nails holding the template in place while tracing the outline of one half.

Flip the template over to create a mirror outline, using the holes left by the nails.

These holes left by the nails will be used as pilot holes for my circle cutter for cutting the wheel arches in the next step.

Step 11

Step 11

Step 11Laminate the second piece to make up a thickness of 1-1/2 inches (38mm) with a wood screw in each corner without any glue, no, not yet.

Using the modified circle cutter for making wheels, I cut a hole through the first layer. This has the advantage of making a wheel just the right size.

It also leaves a v-shape groove in the layer below, which should be removed. This is why I have left it unglued.

I could take it apart and use a chisel or a router to remove the waste as shown in the sectional view.

Step 12

Step 12

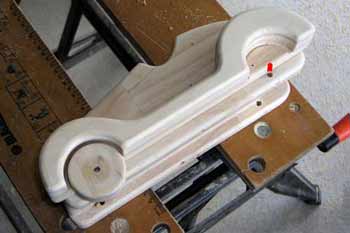

Step 12Here I have cut the fenders to shape, and cut the assembly in half along the centerline.

Not bragging, but I used a round over bit mounted in my home made router table.

The red dots indicate the hole made by the circle cutting. These indentations are going to help locate the holes for the axles.

Step 13

Step 13

Step 13Fix the mudguards in place and drill the holes for the axles.

Wooden Toy Car Plans Free Printable PDF

Your free copy of the printable PDF wooden toy car project.

Making Wooden Toy Wheels

For these toy cars, I made my own wheels using a circle cutter mounted in a drill press.

It may be easier to buy ready made toy wheels.

A selection of from Ebay. Includes wagon wheels, spoked wheels and wheels with treads.Share Your Toy Car Project

Would you like to share photos of the toy car from these plans?

- Home

- Boys Toys

- Wooden Toy Car

- Wooden Toy Car Plans